Snecma has finally found an aircraft for its Silvercrest engine to power after Cessna announced its selection here yesterday for its Longitude super-midsize jet, which is scheduled to enter service in 2017. It has been almost five years since the French manufacturer announced that it was to develop its first business-jet engine program, but finding its first application has proved to be a frustratingly long road.

According to Snecma, the Silvercrest will burn 15 percent less fuel, emit 50 percent less nitrous oxide (NOx) than the CAEP/6 standard and halve the noise footprint “compared to existing engines in the 10,000- to 12,000-pound class.”

The contract with Cessna was signed just a few days ago, Pierre Fabre, Snecma’s chairman and CEO, told an EBACE show press conference. Has his company signed a contract with another business jet manufacturer for the Silvercrest yet? “The only contract we can talk about today is the Cessna one,” replied Fabre. Another hint was he would not say when Silvercrest production begins. The Silvercrest has long been rumored to be selected for the still-under-wraps Dassault Falcon SMS super-midsized jet, which expected to be unveiled next year.

Two Silvercrest engines will provide 11,000 pounds of thrust each on the Longitude. Snecma has started running the engine core, and the first full engine is due to go to test this summer at its Villaroche factory near Paris, which also produces large numbers of CFM International engines for Airbus and Boeing airliners.

Flight testing of the engine is due to start in the first half of 2013 using a Gulfstream GII (see box) and engine certification is pegged for 2015. Eight engines will take part to the certification effort, said Laurence Finet, the program’s general manager. The first engine is now being assembled after full-scale engine development started in the third quarter of 2010.

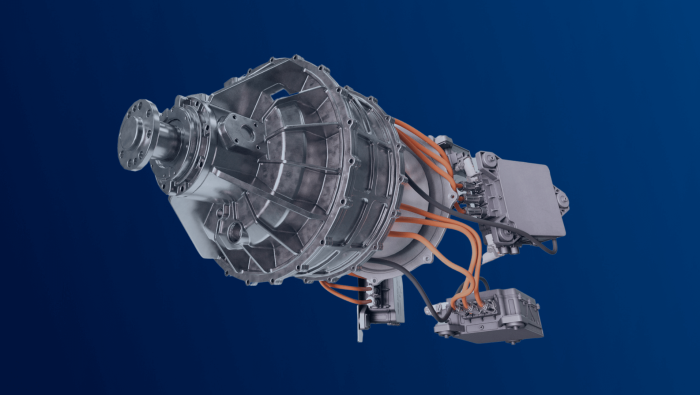

The Silvercrest’s cold section is made of a 42.5-inch fan, a four-stage booster and a five-stage compressor, (including four axial blisks and one centrifugal stage. The 20 fan blades are metallic. The “low-emission” combustor is said to have a high-altitude relight capability. It is followed by a single-stage high-pressure (HP) turbine featuring single-crystal blades and a four-stage low-pressure (LP) turbine.

The HP and LP spools are contra-rotating for better fuel efficiency. The bypass ratio is close to 6:1, Finet added.

In terms of maintenance, Snecma emphasizes the Silvercrest is a “true on-condition engine,” with no fixed interval. No hot-section inspection will be required. Another feature will be in-flight engine monitoring capability.

As the flying testbed for the Silvercrest will be a Gulfstream GII, what about re-engining the venerable business jet? “Why not? We are studying all possibilities,” Laurence Finet, Silvercrest program general manager, told AIN. During the flight tests, the GII will have one of its Rolls-Royce Speys replaced with a Silvercrest. Snecma obtained the GII from sister company Sagem, which had been using it as a testbed for avionics upgrades but no longer needed it.